⚙️ Product Advantages

A boxing ring is more than a platform — it’s the center of every challenge, every victory.

As an experienced boxing ring manufacturer, we engineer each component to balance rigidity, safety, and aesthetics.

-

🏗 Heavy-duty frame: Built from industrial-grade steel for long-term stability.

-

🧩 Modular design: Easy to assemble, transport, and reconfigure for events or gym use.

-

🩶 Shock-absorbing floor system: Multi-layer wooden base with foam and PVC top for optimal cushioning.

-

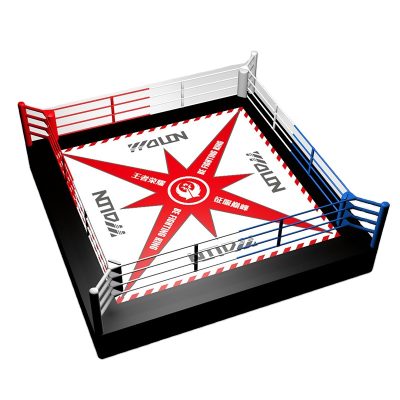

🎯 Custom branding: Aprons, corner pads, and post wraps available with OEM logo printing.

-

🧱 Safety certification: Designed to meet or exceed international boxing federation standards.

Every ring undergoes a 1000kg load test and 2000-cycle assembly simulation to ensure strength and durability.

🛠 Customization Services (OEM / ODM)

Our custom boxing ring factory supports complete customization for gyms, boxing clubs, and international tournaments.

Whether you need a compact 4x4m training setup or a full 6.1×6.1m competition ring, we deliver flexibility in both design and function.

You can choose:

-

Size & Dimensions: 3m, 4m, 5m, or standard 6.1m square formats.

-

Frame Material: Galvanized steel or heavy-duty aluminum alloy for corrosion resistance.

-

Platform Options: Elevated, floor-mounted, or foldable frame designs.

-

Surface Material: Non-slip canvas or PU leather with shock-absorbing foam.

-

Brand Identity: Custom color schemes, corner pads, aprons, and printed event logos.

We also provide OEM support for promotional rings and portable exhibition units.

All designs are compatible with our boxing equipment series for unified branding.

Internal link example:

See our full training gear collection at Boxing Equipment Manufacturers.

🧱 Materials & Structure

We approach ring construction like engineering — precise, modular, and reliable.

1️⃣ Base Frame

Constructed from welded steel or reinforced aluminum tubes with anti-rust coating.

Locking joints ensure stability and quick assembly without heavy tools.

2️⃣ Platform System

Multi-layer composite flooring with wooden panels, foam cushioning, and top canvas cover.

Available in adjustable height levels for professional or gym setups.

3️⃣ Ropes & Posts

Four heavy-duty ropes with adjustable tensioners and padded corner posts for maximum safety.

Rope covers and corner pads can be customized in any brand color.

4️⃣ Ring Apron & Skirt

Durable PVC or canvas skirts available with OEM printed logos or sponsor branding.

5️⃣ Safety Padding

High-density foam padding applied to edges, posts, and frame corners to reduce impact injury risk.

Each component is modular, allowing for easy transportation and reassembly across multiple locations.

Internal link example:

Pair your ring setup with premium Boxing Gloves Manufacturers for full gym outfitting.

📦 MOQ & Wholesale Terms

We provide both single-unit production and large-scale event supply.

Our MOQ for standard boxing rings is 1 complete set, with OEM branding available from the first order.

-

MOQ: 1 unit (standard)

-

Sample time: 15–20 days

-

Production lead time: 30–45 days depending on customization

-

Shipping: Sea or air freight with export-ready wooden crate packaging

-

Installation: Full manual, 3D guide, and optional assembly video support

We ship globally with pre-labeled packaging and reinforced edge protection to prevent damage during transit.

🏭 Why Choose Us

What distinguishes us as a boxing ring manufacturer is precision, reliability, and partnership.

-

🧑🏭 In-house fabrication: From metal welding to logo printing — all done within our own facility.

-

🧪 Rigorous testing: Static load, tension, and assembly cycle testing for each model.

-

🌍 Global supply chain: Rings shipped to clubs, event organizers, and retailers in over 25 countries.

-

⚙️ OEM/ODM expertise: Tailored engineering for both branded and private-label markets.

-

💡 Design innovation: Modular quick-assembly systems and foldable platforms for efficient logistics.

-

♻️ Eco efficiency: Powder-coated steel, recyclable canvas, and low-waste production processes.

We don’t just build boxing rings — we build the stage where champions are made.

❓ FAQs

Q1: What sizes of boxing rings do you offer?

We offer 3m to 6.1m standard sizes and can customize dimensions for gyms or tournaments.

Q2: Can I customize colors and branding for the ring?

Yes. We provide full OEM customization for aprons, corner pads, and ropes with your brand logo or sponsors.

Q3: How long does assembly take?

Standard models take about 1–2 hours to assemble with 2–3 people. All components are modular and tool-friendly.

Q4: Do you offer portable or floor-mounted versions?

Yes. We manufacture elevated competition rings and compact floor-mounted versions for smaller gyms.

Q5: How do you ensure safety and durability?

All rings undergo load testing, anti-slip certification, and inspection of weld joints and foam density before shipment.

🧩 Conclusion

A boxing ring is more than metal and canvas — it’s where focus, training, and honor meet.

At Boxing Manufacturers, we combine industrial precision with athlete insight to build rings that last for years of intense training and championship bouts.

For gyms, event organizers, and distributors, our custom boxing ring factory offers flexibility, performance, and trust.

From blueprint to final installation, we deliver more than equipment — we deliver confidence, one ring at a time.