👋 Introduction

In today’s sports industry, private labeling and customization are more than trends — they’re business strategies.

For distributors looking to stand out in a competitive market, partnering with a boxing equipment factory that offers OEM and ODM services can redefine your product line’s potential.

Let’s explore why OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models are so valuable for boxing gear distributors.

🧾 1. Faster Brand Expansion Without Building a Factory

Not every distributor can invest in its own production line — and that’s where OEM boxing equipment comes in.

By partnering with a manufacturer, you can launch your brand faster, without worrying about machinery, labor, or material sourcing.

Factories already have skilled technicians, stitching lines, and QC systems in place, allowing you to focus purely on sales and marketing.

🧵 2. Custom Designs Tailored to Market Needs

The biggest advantage of OEM and ODM boxing gear is creative flexibility.

Whether you want bold colors, unique stitching, or ergonomic glove shapes, the factory can bring your ideas to life.

ODM services even include new product development — meaning the factory designs products for you based on current trends and feedback from the boxing market.

This keeps your brand fresh and relevant without heavy R&D investment.

💰 3. Better Cost Control and Profit Margins

Working with a boxing supplier on OEM terms ensures cost efficiency through bulk material sourcing and streamlined production.

Factories already manage raw material suppliers, cutting costs per unit as your order volume grows.

Distributors benefit from competitive pricing and stable quality — a combination that improves profit margins while keeping end-customer prices attractive.

🧪 4. Consistency and Quality Assurance

Quality consistency is crucial for brand reputation.

Reliable OEM manufacturers follow strict production steps — material inspection, stitching alignment checks, and random product testing.

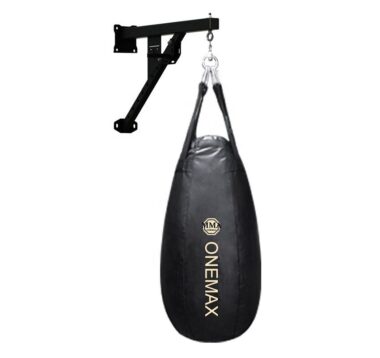

This guarantees that every batch of boxing gloves or punching bags meets the same standard, no matter the size of the order.

In short, OEM manufacturing allows distributors to scale without sacrificing reliability.

🚀 5. Access to Advanced Technology and Innovation

Boxing factories continuously upgrade machinery, foam technology, and materials to meet global standards.

When you work with them through ODM, you gain access to innovations such as improved padding systems, breathable linings, and eco-friendly materials.

This gives distributors a competitive edge — your brand can offer advanced features without having to develop them in-house.

🌍 6. Global Shipping and Private Label Support

Most established manufacturers provide full export support, including logistics coordination, packaging, and labeling.

Factories handle carton markings, barcodes, and custom packaging for retail.

For distributors, this means smoother international delivery and a more professional market presentation.

Working with a factory partner saves time, reduces shipping errors, and helps maintain a consistent global brand image.

🤝 Conclusion

For distributors, OEM and ODM boxing equipment is not just a cost-saving option — it’s a growth strategy.

It allows you to control branding, maintain consistent quality, and scale globally without owning production assets.

Partnering with a trusted boxing equipment factory means you can focus on expanding your network while professionals handle design and manufacturing.

Whether you’re launching a new boxing line or upgrading your current product catalog, OEM and ODM partnerships help you move faster, look sharper, and earn more — all with less risk and more control.